Home » Parts Manufacturing

Precision-Machined Parts for Pumps and Industrial Systems

At Chas. G. Allen, Inc., we provide high-quality, custom parts manufacturing backed by over a century of machining expertise. Our 100,000+ square-foot facility houses state-of-the-art CNC and manual machining centers, allowing us to complete all pump repair and precision parts manufacturing entirely in-house.

We proudly serve critical industries including Aerospace, Military, Nuclear, Energy, and General Manufacturing. Whether you need a single precision-machined component or a full production run, our team delivers unmatched accuracy, reliability, and turnaround time.

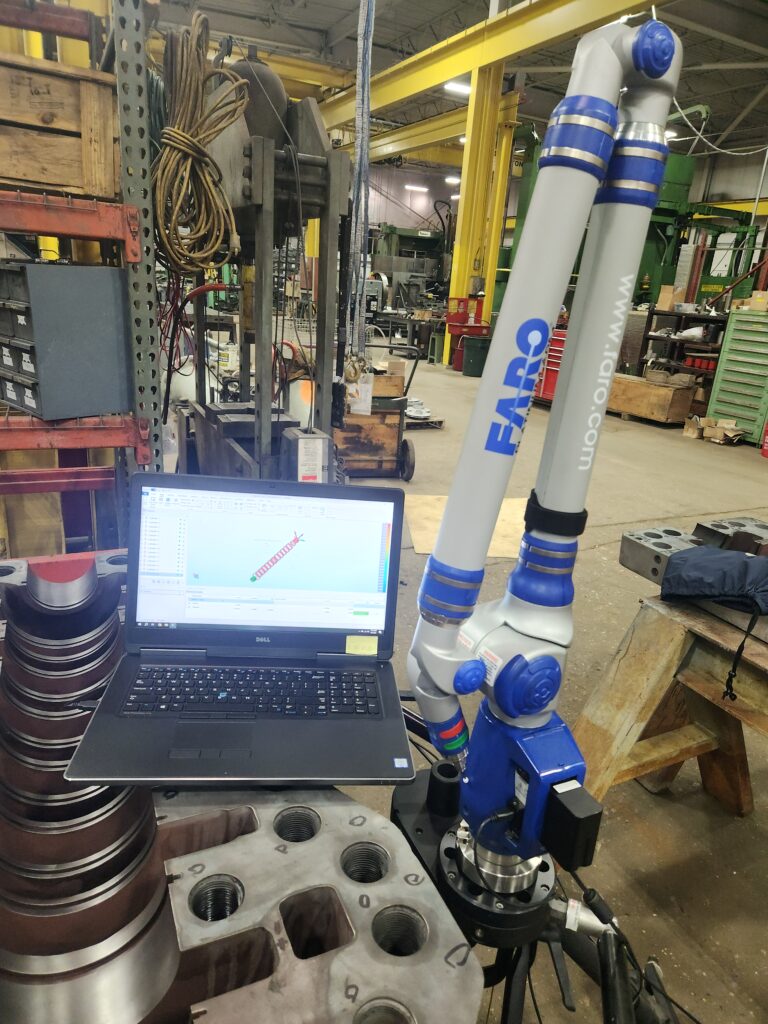

Our capabilities include reverse engineering virtually any component using our portable Faro Arm coordinate measuring machine. We verify material composition with our in-house analyzer and can cast, fabricate, or machine parts to tighter tolerances than the original OEM design.

To maintain strict quality control and scheduling, every step is handled under one roof—from manufacturing wear parts for pump overhauls to final delivery via our own fleet of trucks.

What We Offer

- Custom-Machined Parts – Precision CNC and manual machining for a wide range of metals and materials

- Contract Manufacturing – Scalable, cost-effective solutions for OEMs and industrial partners

- Tight Tolerances – Consistent quality control for high-precision and mission-critical applications

- Fast Turnaround – Agile scheduling, responsive communication, and on-time delivery

- Prototyping to Production – From one-off components to full-scale manufacturing runs

In-House Capabilities

- Large-capacity CNC machining centers for complex geometries

- Full-service turning, milling, drilling, and tapping

- Finishing, deburring, and surface preparation

- Complete assembly, inspection, and quality control

- Reverse engineering with portable CMM (Faro Arm) and material verification

Quality You Can Trust

As an AS9100 and ISO 9001:2015 certified company with ITAR compliance, we meet the highest standards for traceability and performance.

Our quality assurance process includes:

Coordinate Measuring Machine (CMM) inspection

Hardness testing and material verification

Detailed documentation for complete process traceability

Industries Served

- Aerospace and Defense – Complex, high-tolerance components with full compliance

- Energy and Power Generation – Durable parts built for demanding environments

- Industrial Equipment – Custom-machined parts for heavy-duty applications

- Automotive – Prototyping and production for specialized components

- Water and Wastewater – Corrosion-resistant and long-lasting components

Need a Quote?

We specialize in short-run to mid-volume production, complex geometries, and tight-tolerance machining.

Contact us today to discuss your specifications, materials, and lead time—we’ll deliver a solution that meets your needs.